Our Company

MTE Bridgesaw was formed in 2010 because we saw the need to service many different types of machines for stone fabrication across the country. Our goal was to offer the highest level of service, no matter what type of machine you have or where you bought it. We achieve our goal every day. We help hundreds of fabrication shops nationwide stay in production.

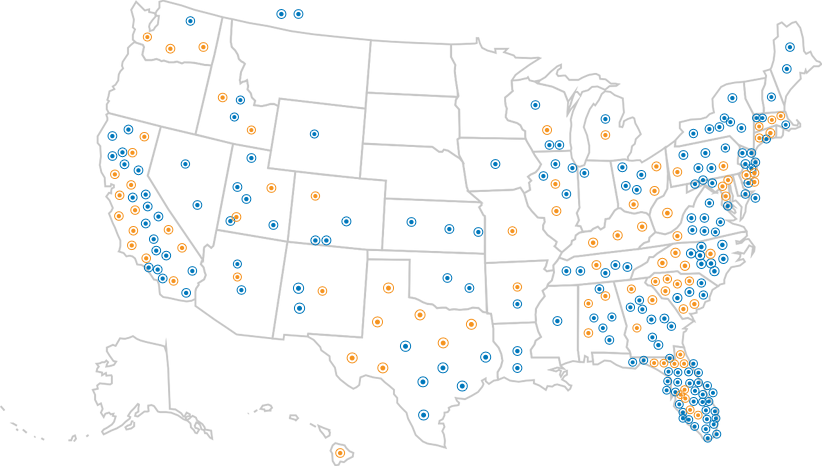

In 2018, we began offering our own line of machines for stone fabrication. Using our years of service and repair experience, we developed a line of machines that are superior, more powerful, cut better, faster, and last longer. We’re pairing our knowledge of service and repair with the best machines in the industry, backed by the best warranty in the industry. We’re offering a line of machines based on a machine we’ve installed and serviced for years. With over 1,000 machines operating in the U.S., our track record reflects quality machines that last.

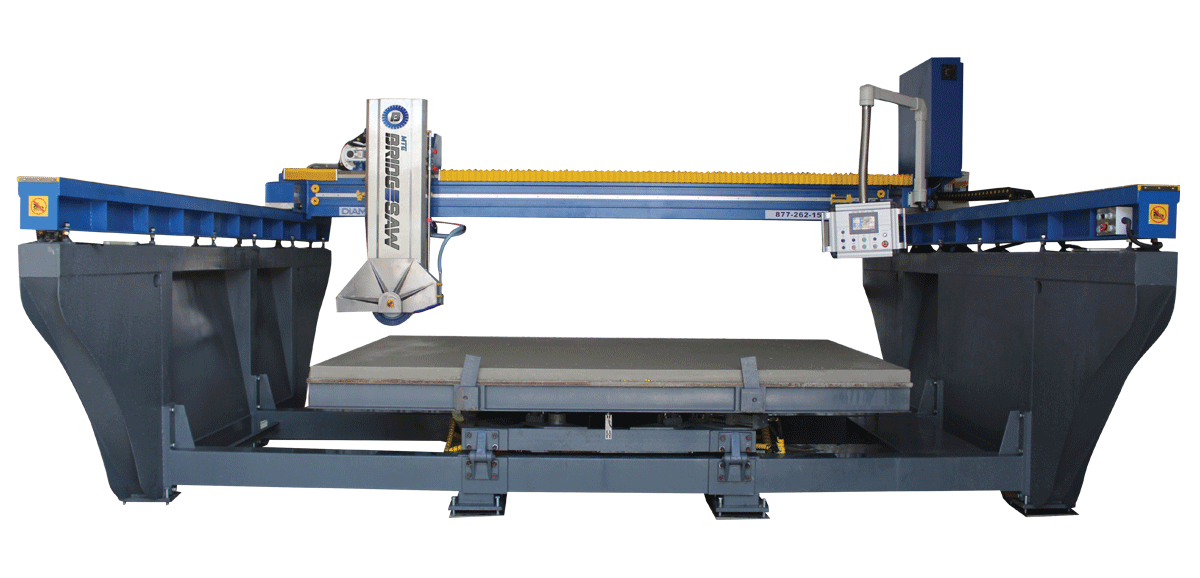

New in 2023, MTE BridgeSaw is introducing the Diamond 3 w/ Miter – “The saw every fabrication shop needs.” This saw is truly the workhorse of the industry as it pairs raw power from its 20 HP main cutting motor with a fully programmable computer, so the only time you lift a finger is to program your next project. Speed up production with 10 ft./minute cutting, automatic rotating table, miter, and plunge cutting. All of this at a price that will make you want to buy two!

View Specifications

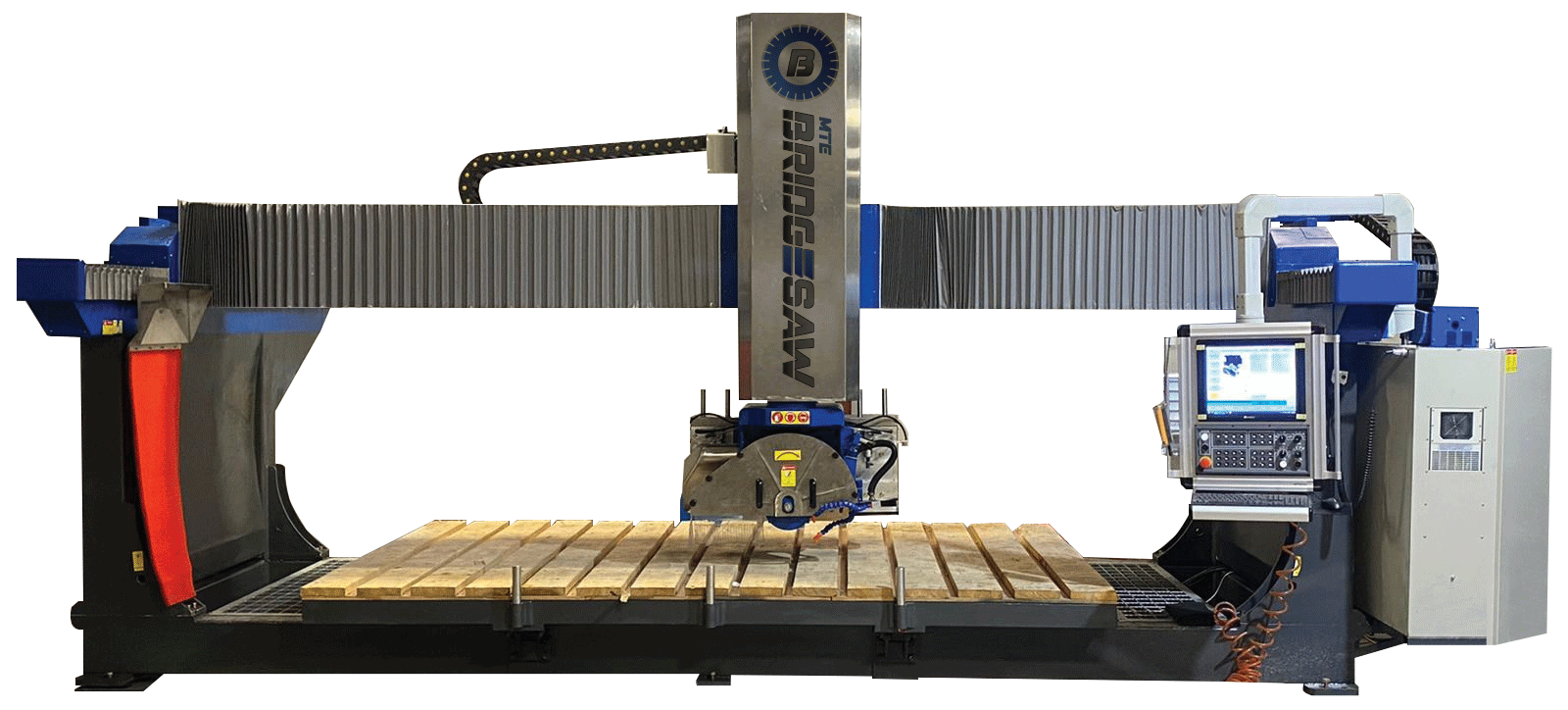

MTE BridgeSaw is introducing the Diamond5 CNC Bridge Saw. With the Diamond5, your shop productivity can skyrocket and revolutionize how your shop functions.

View Specifications

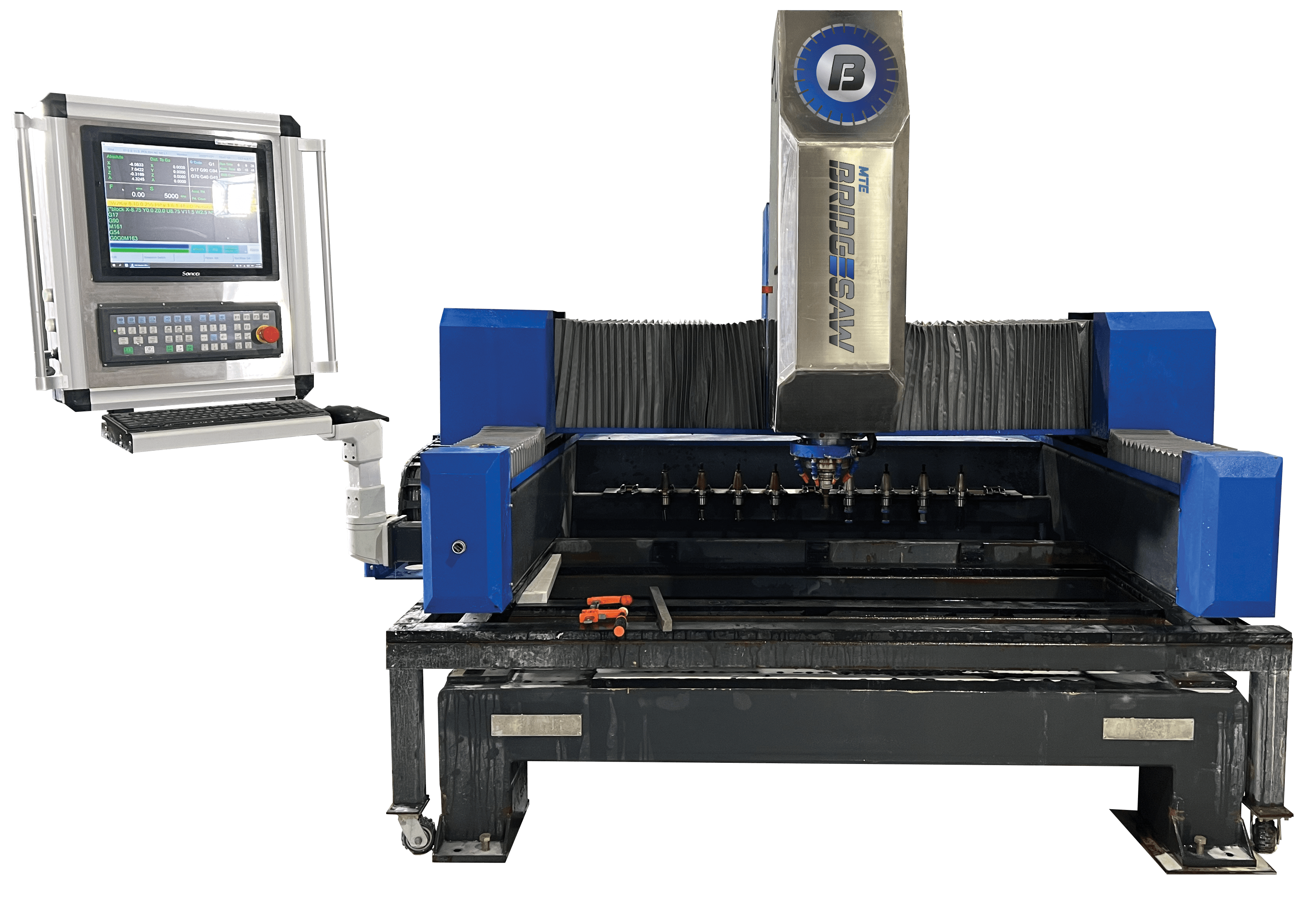

MTE BridgeSaw’s DiamondSC Sink Cutout Machine was designed to overcome one of the biggest bottlenecks fabricators face in production.

View Specifications

New in 2020, MTE BridgeSaw, is introducing the new Diamond11 Vertical Edge Polisher.

Offset Motors – Diamond11 was designed so the motors are out of the way of water, extending the life of motors and working components.

View Specifications

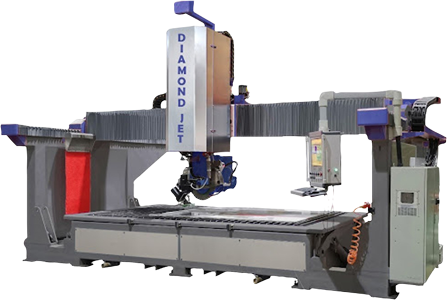

MTE BridgeSaw, is introducing the DiamondJet CNC Waterjet Saw. The DiamondJet optimizes production and efficiency in any shop.

View SpecificationsBelow are the locations of our current equipment installations. MTE BridgeSaw delivers anywhere in the United States.

We’ve been trusted by the granite industry for more than 10 years

Why Choose Us?

Expert

Technicians

Less

Downtime

Any Make

Any Model

Satisfaction

Guarantee

At MTE BridgeSaw, we offer a Clear Cut Guarantee!

Refurbished

- Pre-owned and refurbished equipment for the stone fabrication industry

- Completely refurbished

- Like-new condition