Achieving Precision Cutting in Granite

Granite is a popular choice for countertops, flooring, and other applications due to its durability, beauty, and luxurious appearance. However, working with granite can be a challenging task, particularly when it comes to achieving precision cutting. Precision cutting is essential when working with granite to ensure the final product fits perfectly and looks flawless.

Understanding the Material

Granite is a natural stone that is known for its hardness and durability. It is formed from the slow crystallization of magma deep within the earth’s crust, resulting in a dense and tough material. Due to its hardness, granite can be difficult to cut and shape, requiring specialized tools and techniques. Understanding the properties of granite is essential when it comes to cutting it accurately.

Choosing the Right Tools

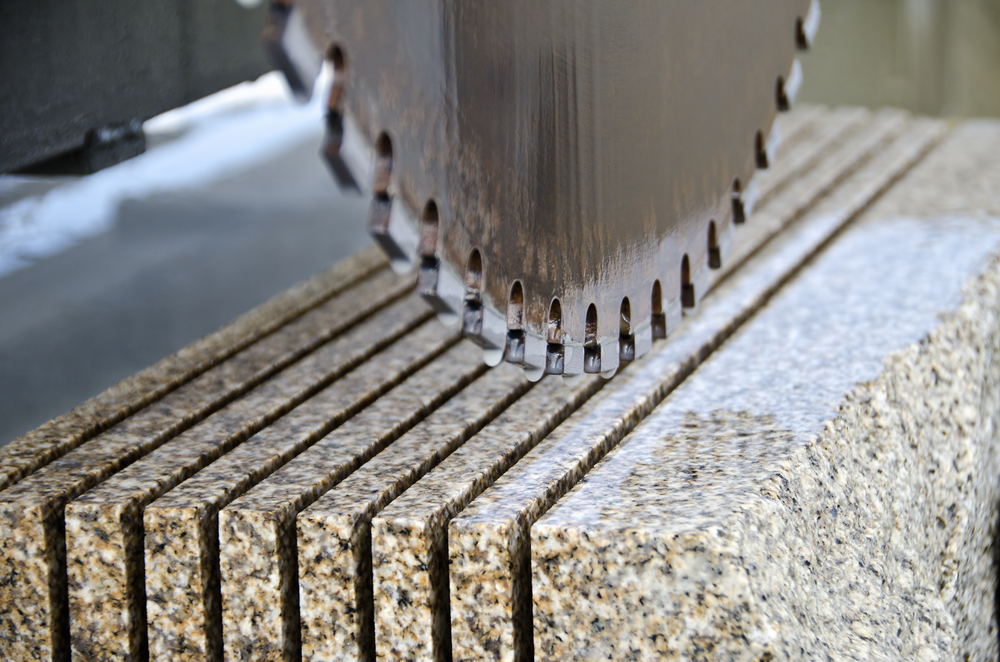

When it comes to cutting granite, using the right tools is crucial for achieving precision cuts. A diamond blade bridge saw is one of the most commonly used tools for cutting granite. Diamond blades are designed to cut through hard materials like granite with ease, thanks to their abrasive properties. Additionally, using a water-cooled diamond blade bridge saw can help keep the blade cool and prevent overheating, which can affect the quality of the cut.

In addition to diamond blade bridge saws, other tools that are commonly used for cutting granite include angle grinders, routers, and hand saws. Each of these tools has its own advantages and disadvantages, depending on the cutting task at hand. Choosing the right tool for the job is essential for achieving precision cuts in granite.

Proper Technique

In addition to using the right tools, employing the proper cutting technique is essential for achieving precision cuts in granite. When cutting granite, moving the blade slowly and steadily through the material is important, allowing the diamond blade to do the work. Rushing the cutting process can result in uneven cuts and jagged edges, compromising the final product’s quality.

Additionally, a guide or template can help ensure that the cuts are made accurately and in the correct dimensions. Templates can be made from luan, plywood, or other materials and can help guide the blade along the desired cutting path. When using a template, it is important to secure it tightly to the granite to prevent any movement during the cutting process.

Safety Precautions

Working with granite can be hazardous, especially when using power tools and sharp blades. Taking proper safety precautions when cutting granite is essential to prevent accidents and injuries. Wearing the appropriate personal protective equipment, such as safety goggles, gloves, and a dust mask, is essential when working with granite.

Additionally, ensuring the work area is well-ventilated and clutter-free can help prevent accidents and injuries. Before starting the cutting process, it is important to read the manufacturer’s instructions for the tools being used and to follow all safety guidelines.

Quality Control

After cutting granite, it is essential to inspect the cuts carefully to ensure they meet the desired specifications. Checking for any chips, cracks, or uneven edges can help identify any issues that must be addressed before installing the final product. Additionally, a straight edge or level can help ensure the cuts are straight and accurate.

If any imperfections are found during inspection, they can be corrected using a grinder or sander to smooth out any rough edges or uneven surfaces. Taking the time to inspect the cuts and make any necessary adjustments can help ensure that the final product looks flawless and fits perfectly.

Achieving precision cutting in granite requires the right tools, proper technique, safety precautions, and quality control. Following these best practices ensures that your granite-cutting projects are completed accurately and professionally.

Contact Us Today

Cutting granite accurately and precisely requires specialized tools, proper technique, safety precautions, and quality control. By following these best practices, you can achieve flawless cuts in granite that will enhance the beauty and durability of your projects. For over ten years, MTE BridgeSaw has been a trusted provider of high-quality diamond blade bridge saws and other cutting tools for the granite industry. Contact us to learn more about our products and services and to find the perfect tools for your granite-cutting needs.

How do you cut stone? Trust MTE BridgeSaw for all your granite-cutting needs. Explore our wide range of high-quality cutting tools and equipment. With MTE BridgeSaw, you can achieve precision cutting in granite and take your projects to the next level.