What Is a Granite CNC Router?

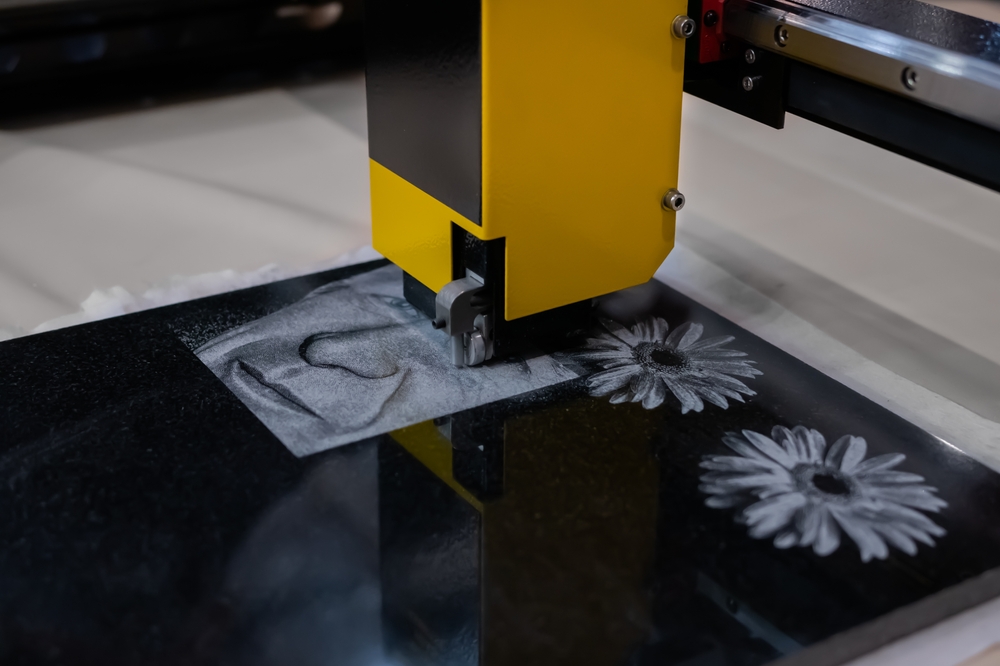

Granite CNC routers revolutionized the stone fabrication industry by introducing impeccable precision and versatility to the cutting process. If you’re involved in stone fabrication for countertops, monuments, or intricate architectural pieces, understanding what a granite CNC router is and how it works could pave the way for more efficient and precise craftsmanship.

Understanding the Basics

What Is a Granite CNC Router?

A Granite CNC (Computer Numerical Control) router is a cutting machine used primarily in stone fabrication that allows operators to execute highly detailed and complex designs with exceptional accuracy. CNC technology brings automation to stone cutting, which means manual intervention is minimal while precision is maximized. By using pre-programmed software, a CNC router guides high-speed rotary tools to cut and shape granite (and other stones) with exact tolerances.

Components of a Granite CNC Router

To understand how a granite CNC router works, it’s essential to recognize its fundamental components:

- Control System: The brain of the operation, where the CNC programming input translates into specific movements of the cutting tool.

- Cutting Tool: Typically fashioned from diamond or carbide, these tools are designed to withstand the extreme hardness of granite and other stones.

- Spindle: The rotating component that holds and drives the cutting tool. Speed and torque are crucial factors influencing spindle choice.

- Workspace (Table): The surface where the stone slab is placed. Features like vacuum tables and clamps help secure the material.

- Axes (X, Y, and Z): These guide the movement of the cutting tool. Advanced models may offer additional rotary axes to enable more complex geometries.

Software Integration

CNC routers employ sophisticated software to turn design files (often in DXF or G-code format) into precise cutting actions. Software versatility enables operators to input drawings and modify parameters easily, making prototyping and production runs highly efficient.

How Does a Granite CNC Router Work?

CAD/CAM Software

The journey of a CNC router begins with Computer-Aided Design (CAD) software, where designs are created or imported. These CAD files are then processed using Computer-Aided Manufacturing (CAM) software, which converts the design data into machine-readable code, typically referred to as G-code.

Setup and Calibration

The next step involves setting up the machine. Technicians place the granite slab on the worktable, securing it with clamps or a vacuum table to ensure it remains stationary during the cutting process. Calibration checks follow, like tool length offset and spindle alignment, making sure everything is in optimal working order.

Cutting Process

Once setup and calibration are complete, the machine executes the G-code commands, guiding the cutting tool along the defined paths. This process involves several passes with varying depths to prevent tool overload and effectively manage heat dissipation. The outcome is a meticulously cut granite piece that matches the design specifications with incredible precision.

Finishing Touches

Depending on the end application, additional processes like polishing, profiling, and edging may be performed post-cutting. Some advanced CNC routers come with integrated finishing tools, further streamlining the workflow.

Advantages of Using a Granite CNC Router

Precision and Consistency

The most significant advantage of using a granite CNC router is its precision and consistency. Manual cutting can lead to inconsistencies and imperfections, but CNC routers ensure each cut is accurate down to the millimeter. This is crucial in applications like countertop fabrication, where even minor errors can be costly.

Efficiency and Speed

CNC routers drastically reduce production time. Their automated nature means they can operate continuously with minimal human intervention, allowing you to take on larger volumes without compromising on quality.

Versatility

These machines are incredibly versatile and capable of executing a wide range of tasks, from simple cuts to intricate designs. This flexibility allows fabricators to expand their service offerings, catering to a broader customer base.

Enhanced Safety

Manual cutting poses various safety hazards, including dust inhalation and the risk of severe injuries from cutting tools. With CNC routers, much of the process is automated, reducing the need for operator proximity to cutting actions and thereby enhancing workplace safety.

Cost-Effectiveness

While the initial investment in a granite CNC router may be substantial, the long-term cost benefits are undeniable. Reduced labor costs, higher production rates, and minimal material wastage collectively contribute to higher profitability.

Why Choose MTE Bridgesaw?

Unmatched Expertise

When it comes to specialized equipment like granite CNC routers, experience matters. MTE Bridgesaw has been a trusted name in stone fabrication since its inception in 2010. Our deep-rooted expertise allows us to offer the highest level of service, ensuring your machines run smoothly and efficiently.

Extensive Product Line

In 2018, we leveraged our extensive industry experience to develop our own line of stone fabrication machines. Our granite CNC routers stand out for their superior precision, speed, and durability. These machines are the culmination of years of field experience and technical know-how designed to meet the varied needs of modern fabrication shops.

Unparalleled Customer Support

Our commitment to customer satisfaction goes beyond merely selling machines. We offer comprehensive support services, including repairs and preventative maintenance, for all types of stone fabrication equipment, regardless of the manufacturer. Our technicians are skilled in handling both in-warranty and out-of-warranty repairs, ensuring minimal downtime for your operations.

Best Warranty in the Industry

We believe in the quality of our machines, and to back that belief, we offer the best warranty in the industry. This assurance reflects the durability and reliability of our equipment, giving you peace of mind that your investment is well-protected.

Nationwide Reach

Our reach is expansive, and we have over a thousand machines operating across the United States. This extensive deployment underscores our ability to meet the needs of diverse fabrication shops, irrespective of location. Our nationwide network ensures that help is always available whenever needed.

Contact Us Today

In the competitive world of stone fabrication, leveraging state-of-the-art technology like a granite CNC router can be a game-changer. These machines offer unparalleled precision, speed, and versatility, making them indispensable for modern fabricators. Understanding how they work and their countless benefits can help you make informed decisions for your business.

If you want to invest in a granite CNC router or upgrade your current stone fabrication setup, MTE Bridgesaw is your ideal partner. Our industry-leading machines, coupled with unmatched customer support and the best warranty in the industry, ensure you get the highest value for your investment.

Don’t wait—elevate your stone fabrication capabilities today! Explore our extensive product range or contact our expert team to find out how we can help keep your machines running and making you money.