Safety Tips When Operating a Bridge Saw

Operating a stone cutting saw, such as a bridge saw, requires precision, attention to detail, and, most importantly, a strong focus on safety. These powerful machines are indispensable in stone fabrication, enabling intricate cuts and designs that enhance the quality of various projects. However, improper handling can lead to accidents, injuries, and damage to the equipment.

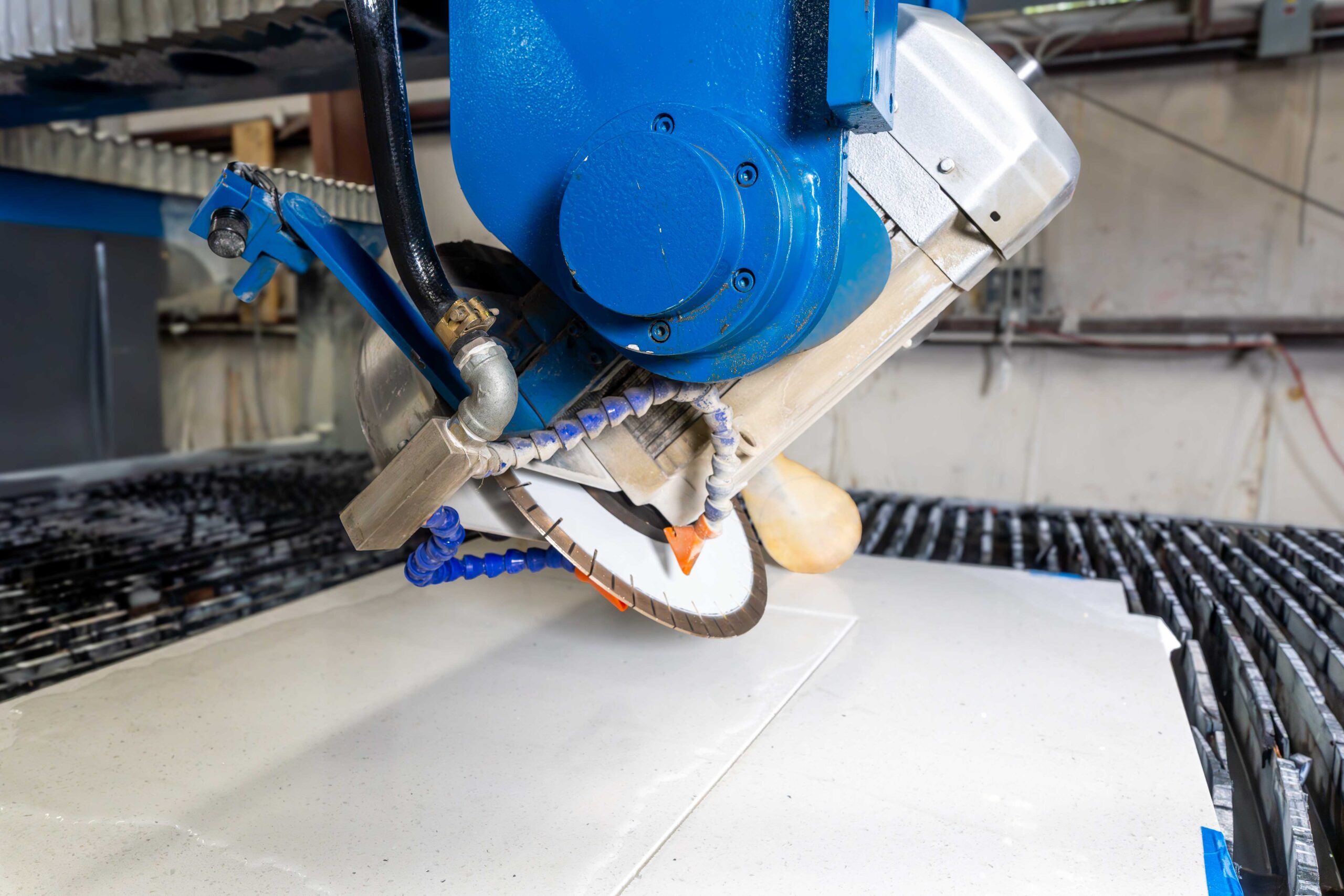

Understanding Your Bridge Saw

Before diving into safety tips, it’s essential to understand the machinery. A bridge saw is a robust stone cutting saw designed to cut slabs of stone such as granite, marble, and quartz with precision. Key components include the bridge, blade, motor, and control panel. Familiarizing yourself with the machine’s functions and capabilities is the first step to operating it safely.

Wear Appropriate Personal Protective Equipment (PPE)

One of the easiest ways to reduce risk is by wearing the right PPE. Stone cutting generates dust, debris, and noise, all of which can harm operators without proper protection. Ensure you have:

- Safety goggles: Protect your eyes from flying debris.

- Hearing protection: Minimize exposure to high noise levels.

- Respiratory masks: Prevent inhalation of stone dust, which can lead to respiratory issues over time.

- Steel-toed boots: Safeguard your feet from falling slabs or tools.

- Cut-resistant gloves: Protect your hands while handling sharp edges or materials.

Conduct a Pre-Operation Inspection

Before starting the saw, inspect the machine thoroughly to identify any potential issues. Pay attention to:

- Blade condition: Ensure the blade is sharp, clean, and free of cracks or damage.

- Power connections: Check for secure electrical connections to avoid short circuits or electrocution.

- Water cooling system: Verify that the water supply for blade cooling is functioning properly to prevent overheating.

- General cleanliness: Remove debris, dust, or loose materials that may interfere with the saw’s operation.

Follow the Manufacturer’s Guidelines

Each bridge saw has specific operating instructions and limitations. Always refer to the manufacturer’s manual for:

- Recommended blade sizes and types.

- Maximum cutting depth and material thickness.

- Maintenance schedules and procedures.

- Proper start-up and shut-down protocols.

Strict adherence to these guidelines not only ensures safety but also extends the lifespan of your machine.

Secure the Material Properly

A securely held slab is critical for precision cuts and operator safety. Always:

- Use appropriate clamps or supports to hold the stone slab in place.

- Check that the material is flat and stable on the cutting table.

- Avoid cutting pieces that are too small or irregularly shaped unless proper jigs or fixtures are in place.

Loose or unstable materials can shift during cutting, leading to inaccurate results or dangerous accidents.

Operate at the Correct Speed

Bridge saws are designed to operate at specific speeds based on the material being cut. Using the correct speed is vital for:

- Preventing blade damage.

- Avoiding overheating.

- Ensuring clean, precise cuts.

Consult the user manual or your blade’s specifications to determine the ideal speed for each type of stone.

Stay Focused and Avoid Distractions

Operating a stone cutting saw demands your full attention. Distractions can lead to mistakes that jeopardize safety. Follow these best practices:

- Do not use the saw while tired or under the influence of medication or alcohol.

- Avoid using mobile phones or other devices during operation.

- Keep unauthorized personnel away from the work area.

Maintain a Clean Work Area

A cluttered workspace increases the risk of accidents. Ensure that:

- The area around the saw is clear of obstacles.

- Tools and materials are organized and stored properly.

- Spills, such as water or oil, are cleaned immediately to prevent slips and falls.

Use the Water Cooling System Effectively

Bridge saws rely on water to cool the blade during operation. Proper use of the water cooling system prevents overheating and prolongs the blade’s life. Ensure:

- The water supply is clean and free of debris.

- The flow rate is sufficient to keep the blade cool.

- Hoses and connections are intact and leak-free.

Neglecting the cooling system can lead to blade failure, heat-related injuries, and reduced cutting precision.

Be Prepared for Emergencies

Even with all precautions in place, emergencies can still occur. Operators should:

- Know the location of emergency stop buttons on the machine.

- Keep a fire extinguisher nearby, especially when working with combustible materials.

- Have a first-aid kit readily accessible.

- Train all personnel on proper procedures for addressing injuries, electrical faults, or equipment malfunctions.

Regular Maintenance and Repairs

Preventive maintenance is crucial for the safe and efficient operation of any stone cutting saw. Schedule regular check-ups to address:

- Blade wear and replacement needs.

- Lubrication of moving parts.

- Calibration of cutting settings.

- Inspection and repair of electrical components.

When repairs are required, rely on professionals like MTE Bridgesaw to ensure that the job is done correctly and safely.

Train Operators Thoroughly

Every operator should receive comprehensive training on how to use the bridge saw. Training should cover:

- Machine setup and operation.

- Material handling techniques.

- Recognizing warning signs of equipment malfunction.

- Emergency protocols.

Proper training reduces accidents and builds confidence in operators, leading to better productivity and quality.

Avoid Overloading the Machine

Overloading a bridge saw can lead to dangerous conditions, including motor strain, blade damage, and accidents. Always:

- Operate within the machine’s specified weight and size limits.

- Avoid cutting multiple slabs simultaneously unless the machine is designed for such use.

- Monitor the motor for unusual sounds or vibrations.

Monitor Dust Control

Stone dust is a significant hazard in stone fabrication. Prolonged exposure can lead to respiratory illnesses such as silicosis. Use proper dust control methods, including:

- Wet cutting techniques.

- Dust extraction systems.

- Respiratory masks as part of PPE.

Implementing these measures ensures a safer work environment for all.

Shut Down Safely

When your cutting tasks are complete, follow these steps to shut down the saw safely:

- Turn off the blade and allow it to come to a complete stop.

- Disconnect the power supply.

- Clean the machine and work area, removing any debris or residual materials.

- Inspect the machine for any signs of wear or damage that need attention before the next use.

Partner with MTE Bridgesaw for Maintenance and Repairs

Proper operation and maintenance of your stone cutting saw are critical to ensuring safety, efficiency, and longevity. At MTE Bridgesaw, we understand the challenges of maintaining and repairing your bridge saw or CNC equipment. That’s why we’re committed to providing the highest level of service, so you’ll always choose us for your maintenance and repair needs.

We know that machine maintenance and repair aren’t always fun or convenient, but our goal is to make the process as easy as possible. We genuinely care about your machines and your experience, and it shows in our dedication to quality and value. First-time customers continually become long-term clients, choosing us for all their stone fabrication equipment needs.

Don’t let maintenance concerns slow you down—call MTE Bridgesaw today for an inspection and see what our commitment to quality is all about. Together, we’ll keep your equipment running smoothly and safely for years to come.