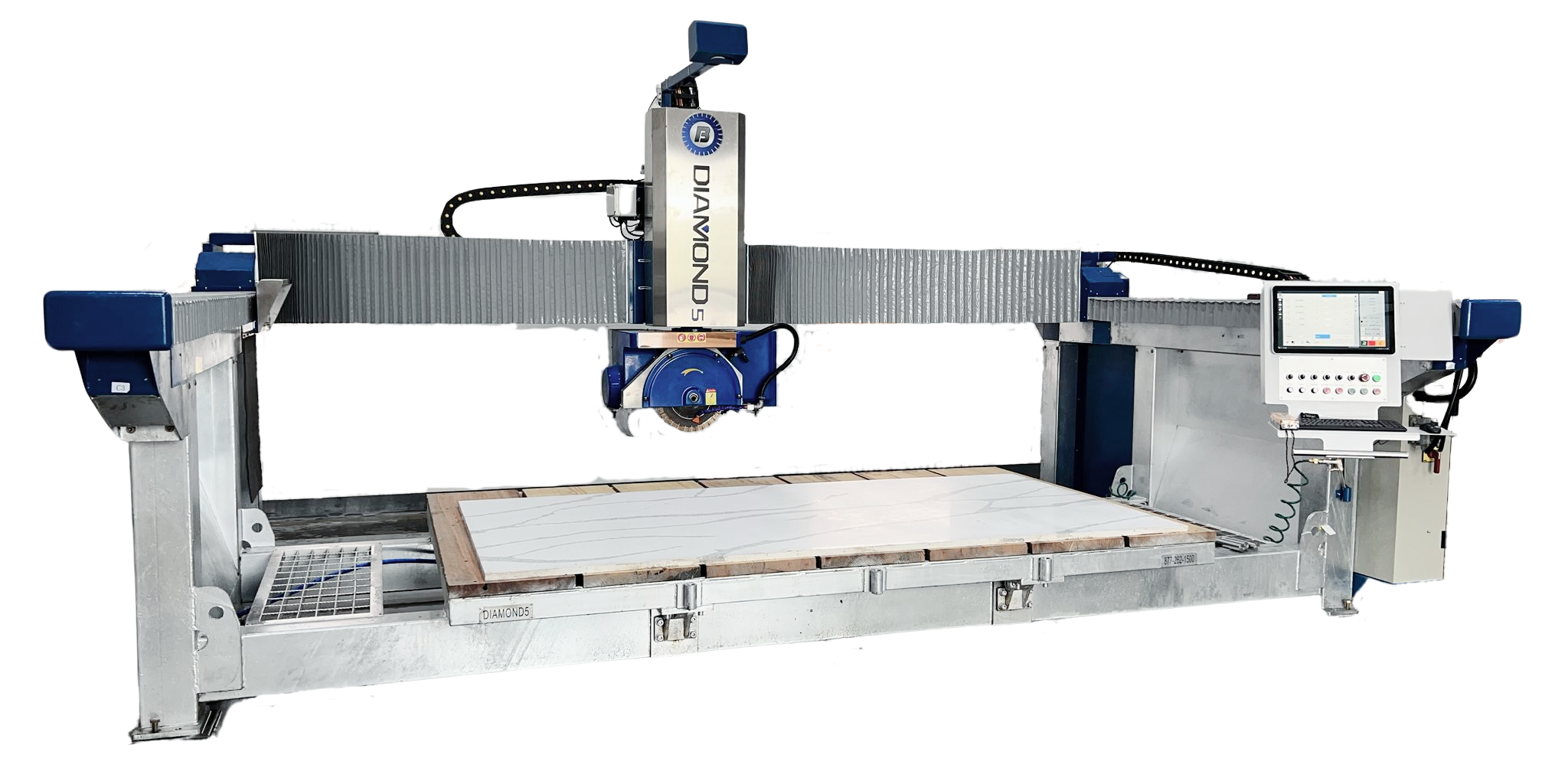

Diamond 5

From Vision to Precision

Features

- Galvanized steel construction

- Automatic tool measurement

- Hydraulic tilting table

- 5 interpolated axis for complex cutting

- 24,000 rpm secondary spindle for sink cutouts & inside corners

- Vacuum system for material saving and nesting

- Camera vision system for slab setup

- Laser templating ready

- Slab thickness probe

- Zeus CAD/CAM software suite

- Installation & Training with an MTE BridgeSaw Technician included

- Clear Cut Guarantee – 3-year industry best warranty

Software

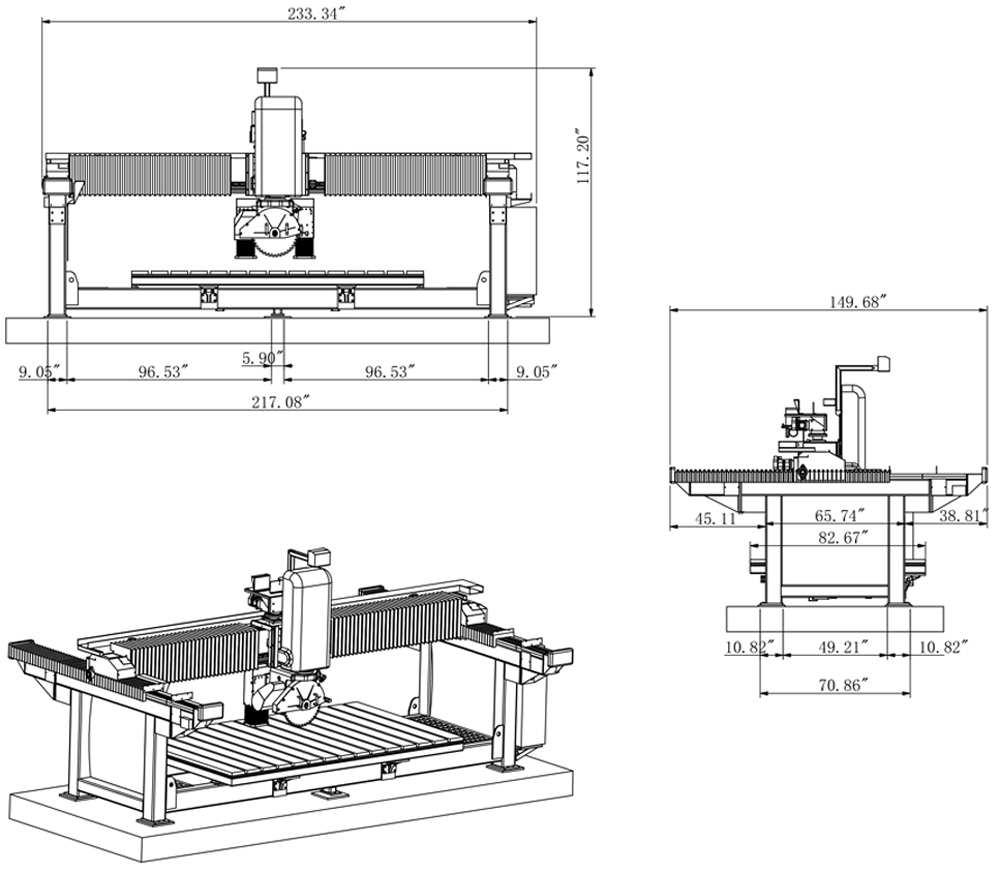

Specifications

MOTOR: 30hp

BLADE SIZE: 14″-18″

HEAD ROTATION: 360°

HEAD TILT: Up to 270°

MAX CUTTING THICKNESS: 7″

HEAD ROTATION: 360°

HEAD TILT: 90°

CNC Control System: ESA

CNC Software: Zeus Plus

WORK ENVELOPE: 138″ x 82″

MITER WORK ENVELOPE: 128″ x 82″

POWER: 220v, 3-phase, 80amp

AIR: 100psi, 10cfm

WATER: 8gpm

FOOTPRINT: 19′ x 11′ x 10′

WEIGHT: 12,000lbs