Finding the Best Diamond Bridge

In industries where precision is critical, finding the right tools and equipment is essential to success. One such crucial tool is the diamond bridge, a key component in high-precision cutting and machining processes. Whether you’re working in stone fabrication, glass cutting, or other industries that require exacting standards, the diamond bridge plays a central role in delivering top-quality results.

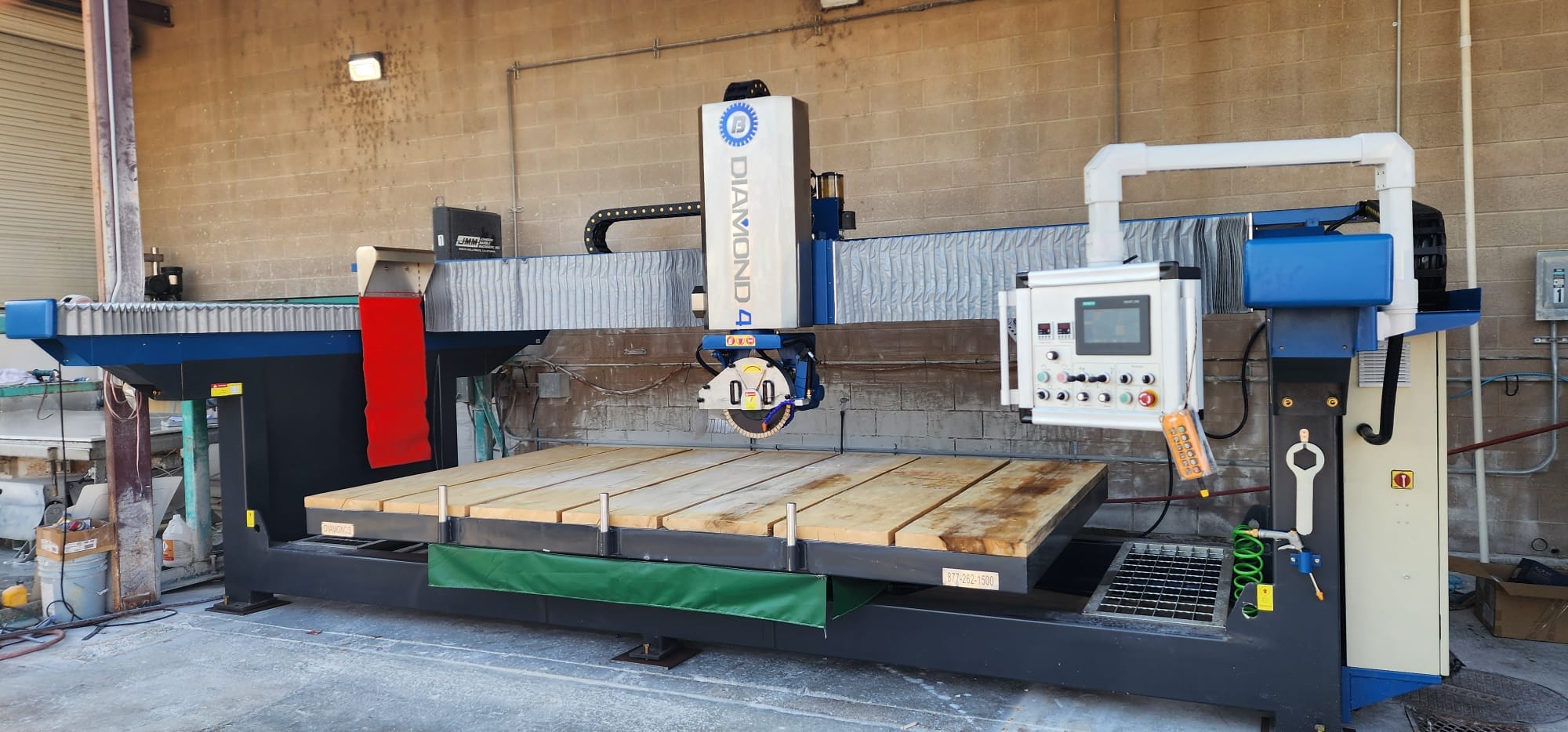

At Machine Tech Enterprises, LLC, we specialize in providing cutting-edge solutions for various industrial applications, including diamond bridge saws and other high-performance machinery. We also understand that choosing the best diamond bridge for your operations can significantly impact your efficiency and overall production quality. So let us guide you through the essential factors to consider when selecting the best diamond bridge, as well as offer insight into how these tools can elevate your projects.

1. What Is a Diamond Bridge?

Before diving into the details of how to choose the best diamond bridge, it’s important to clarify what exactly this tool is and how it works. A diamond bridge is a type of saw used in cutting hard materials such as stone, glass, ceramics, and even metal. The term “diamond” refers to the industrial-grade diamond embedded into the saw blade, which allows for high-precision cutting of extremely tough materials. The “bridge” component refers to the structure that supports the blade and the material being cut.

Diamond bridge saws are primarily used in industries like:

- Stone fabrication: Cutting marble, granite, quartz, and other natural stones for countertops, flooring, and architectural elements.

- Glass cutting: Creating precision cuts in glass for both industrial and decorative purposes.

- Ceramic tile cutting: Shaping ceramic tiles for construction and interior design.

- Metal fabrication: Some models are designed to cut specific types of metals with accuracy and efficiency.

2. Key Factors to Consider When Choosing a Diamond Bridge

When selecting a diamond bridge saw, it’s essential to evaluate several key factors to ensure the tool meets your specific needs. Each project or material may have different requirements, and choosing the right saw can improve precision, speed, and overall project outcomes.

1. Blade Size and Material Compatibility

One of the most critical factors when choosing a diamond bridge saw is the size and type of blade. Diamond blades come in various sizes, and the right one for your project depends on the material you’re cutting and the thickness of that material.

Blade Size:

- Small blades (10 to 12 inches): Ideal for smaller, more delicate materials such as ceramic tiles or thinner slabs of stone.

- Medium blades (14 to 18 inches): Suitable for a wide range of materials, including thicker stone slabs like granite and marble.

- Large blades (20 inches or more): Used for heavy-duty applications where large pieces of stone, glass, or other materials need to be cut with precision.

The blade’s diameter affects the depth of cut, so it’s important to choose the correct blade size to handle the thickness of your material.

Material Compatibility:

Each blade is designed for specific materials, and the diamond composition can vary depending on the intended use. Make sure the blade you choose is compatible with the material you’re working with, whether it’s granite, marble, quartz, ceramic, or glass. Some diamond bridge saws are versatile enough to handle a variety of materials, while others are specialized for specific types of cutting.

2. Cutting Capacity and Table Size

The cutting capacity of a diamond bridge saw refers to the maximum size and thickness of the material it can cut. This is often determined by the size of the saw’s cutting table and the length of the bridge itself.

Cutting Table:

- Small cutting tables are ideal for smaller projects, such as cutting tiles or smaller slabs of stone.

- Larger cutting tables offer greater flexibility and allow you to work with larger slabs, which is especially important if you’re cutting large countertops, flooring pieces, or architectural stonework.

The table should be sturdy and capable of supporting the weight of your material without shifting or vibrating, as this can affect the precision of your cuts. At Machine Tech Enterprises, LLC, we offer diamond bridge saws with various table sizes and configurations, ensuring that our clients can find the perfect match for their cutting needs.

3. Precision and Control

Accuracy is one of the most important aspects of cutting, particularly in industries where exact measurements are crucial to the final product. The precision of a diamond bridge saw is influenced by the machine’s design, the stability of the cutting table, and the quality of the blade. CNC (Computer Numerical Control) systems are often used in diamond bridge saws to provide enhanced precision and automation.

CNC Control Features:

- Programmable cutting paths: CNC systems allow for pre-programming of cutting patterns and shapes, reducing the likelihood of human error and ensuring consistent results.

- Automated movements: A CNC-controlled diamond bridge saw automates the movement of the blade, ensuring smooth, consistent cuts.

- Adjustable speed and pressure: Being able to control the speed and pressure of the blade gives you greater flexibility when working with different materials, allowing you to achieve the best results for each project.

If your business requires precise, repeatable cuts, investing in a CNC-equipped diamond bridge saw is likely the best choice.

4. Water Cooling Systems

Diamond bridge saws generate significant heat during operation due to the friction between the blade and the material being cut. Excessive heat can cause damage to both the blade and the material, so most diamond bridge saws are equipped with water cooling systems to manage heat during cutting.

Benefits of Water Cooling:

- Blade longevity: Water helps cool the blade, reducing wear and tear and prolonging the life of the tool.

- Improved cutting quality: Cooling the material and blade minimizes the risk of cracking or chipping, especially with delicate materials like glass or ceramics.

- Dust reduction: Water cooling helps suppress dust particles generated during cutting, creating a cleaner, safer working environment.

Make sure that any diamond bridge saw you’re considering has an efficient water cooling system to protect both the equipment and the material being cut.

5. Durability and Build Quality

A diamond bridge saw is a significant investment, so it’s important to choose a machine that is built to last. Look for saws made from high-quality materials, such as stainless steel or other corrosion-resistant metals, to ensure the machine can withstand the rigors of heavy use. Additionally, the saw’s design should prioritize stability and strength, especially if you’re cutting large, heavy slabs.

At Machine Tech Enterprises, LLC, we offer diamond bridge saws built to handle demanding cutting environments. Our machines are constructed from durable materials and designed for long-term performance, making them a reliable choice for businesses that require consistent precision cutting.

3. Choosing the Right Diamond Bridge for Your Industry

Different industries have varying needs when it comes to diamond bridge saws, so it’s important to consider your specific applications when choosing the right equipment. Below, we’ll explore how diamond bridge saws are used across various industries and what factors are most important in each sector.

1. Stone Fabrication

Stone fabricators rely on diamond bridge saws for cutting large slabs of granite, marble, quartz, and other natural stones. Precision is critical in this industry, as even slight deviations can result in wasted materials and flawed products. When choosing a diamond bridge saw for stone fabrication, consider the following:

- Blade size and cutting capacity: Ensure the saw can handle the thickness and size of the stone slabs you work with.

- CNC capabilities: Automated cutting paths are especially useful for creating intricate designs, such as custom countertops or flooring inlays.

- Durability: The machine should be capable of withstanding heavy daily use, as stone fabrication often involves cutting dense, hard materials.

2. Glass Cutting

Glass cutting requires exceptional precision and care, as glass is a brittle material that can easily crack or shatter if not cut correctly. Diamond bridge saws designed for glass cutting should prioritize precision, with smooth, clean edges that minimize the risk of damage. In this industry, look for:

- Fine diamond blades: These blades should be designed specifically for glass, ensuring clean, chip-free cuts.

- CNC control: Automated cutting systems ensure the exacting precision needed for intricate glass designs.

- Water cooling: Essential for keeping the blade cool and preventing heat from affecting the glass.

3. Ceramic and Tile Cutting

Ceramic and tile cutting is another area where diamond bridge saws excel. In this industry, precision is important for ensuring that tiles fit perfectly in their designated space, whether for flooring, wall coverings, or other applications. Key factors for ceramic and tile cutting include:

- Blade compatibility: Ensure the blade is designed for ceramic materials, as this will ensure smoother cuts and reduce chipping.

- Water cooling: Helps prevent overheating and cracking during the cutting process.

Machine Tech Enterprises, LLC: Your Source for High-Quality Diamond Bridge Saws

At Machine Tech Enterprises, LLC, we specialize in providing high-quality diamond bridge saws that meet the needs of professionals across various industries. That means that whether you work in stone fabrication, glass cutting, or tile production, we offer reliable, durable machines that deliver precision cutting and superior performance. So if you’re looking to upgrade your equipment or need expert guidance on choosing the best diamond bridge saw for your business, contact us today. With our expertise and industry-leading products, Machine Tech Enterprises, LLC is your trusted partner in precision cutting.